Please note that the information below is based on speculation and may differ from the actual facts.

※Apple Micro OLED Supply chain: consists of eMagin+TSMC+SONY

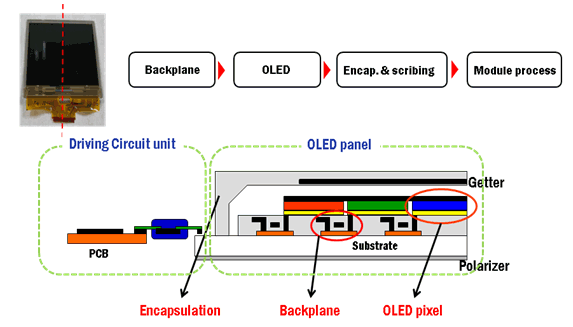

- eMagin: Back Plane Design + OLED Deposition + Encap, Post Process

- TSMC: Back Plane/Driving Circuit Unit production

- SONY: Driving Circuit Unit Design

-In general, when TSMC, SONY, and eMagin collaborate to make OLEDos (MicroOLED), it is easy to think that large companies such as TSMC and SONY will play an important role, and small companies such as eMagin will play a small role.

-But in reality, eMagin plays the most important role as the world's top producer of OLEDos, and TSMC and SONY seem to play an additional role.

※What is the role of eMagin?

-Possess advanced back plane design technology.

-Received Back Plane manufactured by TSMC and Driving IC manufactured by SONY, deposited OLED material on it, and manufactured OLEDos products through encapsulation, cell, and module processes.

-Possess dPd (Direct Patterning display) deposition technology.

-With eMagin's dPd deposition technology, the current brightness can be up to 10,000cd/m2. Implementation potential of over 28,000 cd/m2.

- Encapsulation, cell, and modularization are not difficult skills.

-eMagin is seen as a key player as a company with the most important Back Plane design + Micro OLED deposition technology in the display process.

※What is the role of TSMC?

-TSMC: In charge of manufacturing the Back Plane (drive layer).

-It is estimated that it will be made of silicon wafer to realize low power and miniaturization.

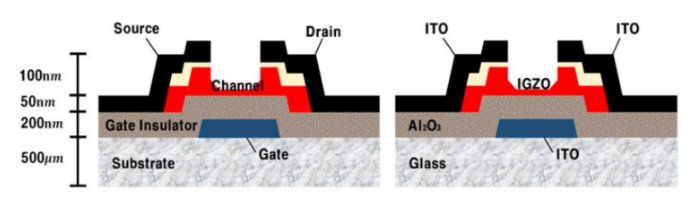

-A typical display driving layer consists of a substrate (Glass, Polyimide, Silicon) + TFT (a-Si, Oxide, LTPS, LTPO).

-Most of the substrates use glass with good light transmittance for TVs and smartphones.

-OLED for high-end smartphones uses a plastic material called Polyimide to make it light and flexible.

-Silicon substrate has excellent performance, but has never been used for mass production because of its high price and low light transmittance.

-However, TFT with high performance is needed to drive next-generation displays, and it is estimated that it will be manufactured based on silicon, but with improved transparency due to material changes like IZGO.

-TFT has switch TFT and driver TFT.

-Switch TFT serves to turn the sub pixel on and off. The driving TFT serves to transfer current to the sub-pixel.

-TFT is also classified into a-Si, Oxide, LTPS, and LTPO depending on the constituent material and process temperature.

-TSMC is also expected to be in charge of manufacturing TFTs on silicon substrates, and from the standpoint of TSMC, it is expected that this will be sufficient for legacy nodes rather than high-end nodes.

-Apple is a very important customer for TSMC, so I think it's a concept that provides a service.

-Since the difficulty of the process does not seem to be difficult, it seems that Samsung Electronics, SK Hynix and other semiconductor foundries will be able to manufacture it using the existing semiconductor process.

-Samsung Display and LG Display are also belatedly jumping into micro-OLED, but it seems that it will be difficult to manufacture TFT on a silicon substrate by itself. (In the past, display companies directly produced Glass, Polyimide substrate + TFT)

Samsung Display is also jumping into micro OLED development... Requested by Samsung Electronics, etc. - The Elec (thelec.kr)

※What is the role of SONY?

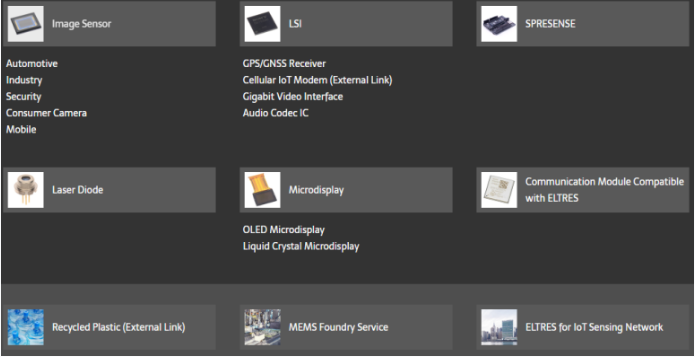

-SONY is not only in the film, music, and PlayStation businesses, but is also famous for CIS image sensors and sensor semiconductors.

-Based on these semiconductor design/manufacturing technologies, we also manufacture Driving Circuit Unit semiconductors for Microdisplay.

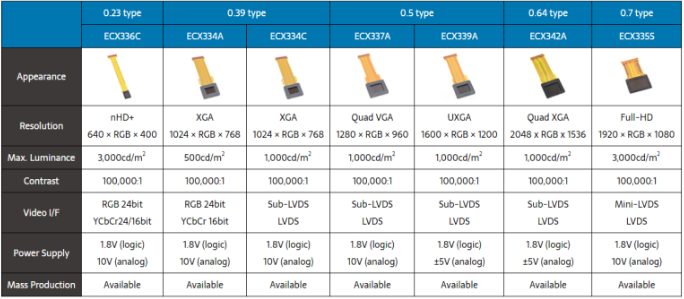

-Max Luminance up to 3,000cd/m2 is listed.

-Advantages of Sony's products

Stable and higher uniformity

Ultra-high contrast: 100,000:1

Ultra-fast response speed: 0.01 ms or less

Integration of driving circuits onto silicon backplane

Stand-alone panel module realized with no additional driver chips required for operation.

Example) Integrated circuits for ECX335B

Vertical and horizontal scan drivers

8-bit digital-to-analog converter

Gamma reference voltage generation circuit

Timing controller (Tcon)

-Sony has its own fab, so it is highly likely to produce directly, but since it is also strengthening collaboration with TSMC, it may be possible to outsource it.

-Since it is possible to manufacture by integrating Driving Circuits into the Silicon Backplane, it seems advantageous to outsource production from TSMC and integrate B/P+Driving ICs at once. (SONY plays the fabless role here)

'Investing Ideas > eMagin' 카테고리의 다른 글

| eMagin Corporation (EMAN) Q2 2022 - Earnings Announcement by CEO Andrew Sculley (0) | 2022.08.20 |

|---|